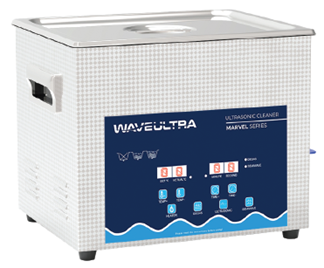

Our PCB cleaners use ultrasonic technology to remove contaminants, flux residues, and other particles from PCBs and associated components, ensuring optimal electrical performance and reliability. These systems primarily use water-based cleaning solutions or specialized PCB cleaning detergents to remove flux residues, solder paste, dust, and other contaminants effectively. Ultrasonic cleaning in PCB applications is efficient, reducing the need for manual cleaning and minimizing the risk of introducing defects in electronic components. The gentle yet effective cleaning process of ultrasonics ensures that PCBs and electronic components are cleaned without causing damage, preserving their structural integrity and electrical performance. They contribute to the quality, reliability, and efficiency of electronic manufacturing and maintenance processes. Features: o No Human Interference o Preserves Electrical Performance o Highly Reliable Technical Specifications: o Brand: Waveultra o Power Output (Ultrasonic): 1 kW o Total Volume / Capacity: 48 Litres o Power Input: 230V AC o Frequency: 40 / 68 kHz o Material: SS304 o Basket Size(L x W x H): 550 x 350 x 150 mm o Transducers: PZT type o Cleaning Agent: IPA o Tank Size (L x W x H): 600 x 400 x 200 mm o No. of Stages: One