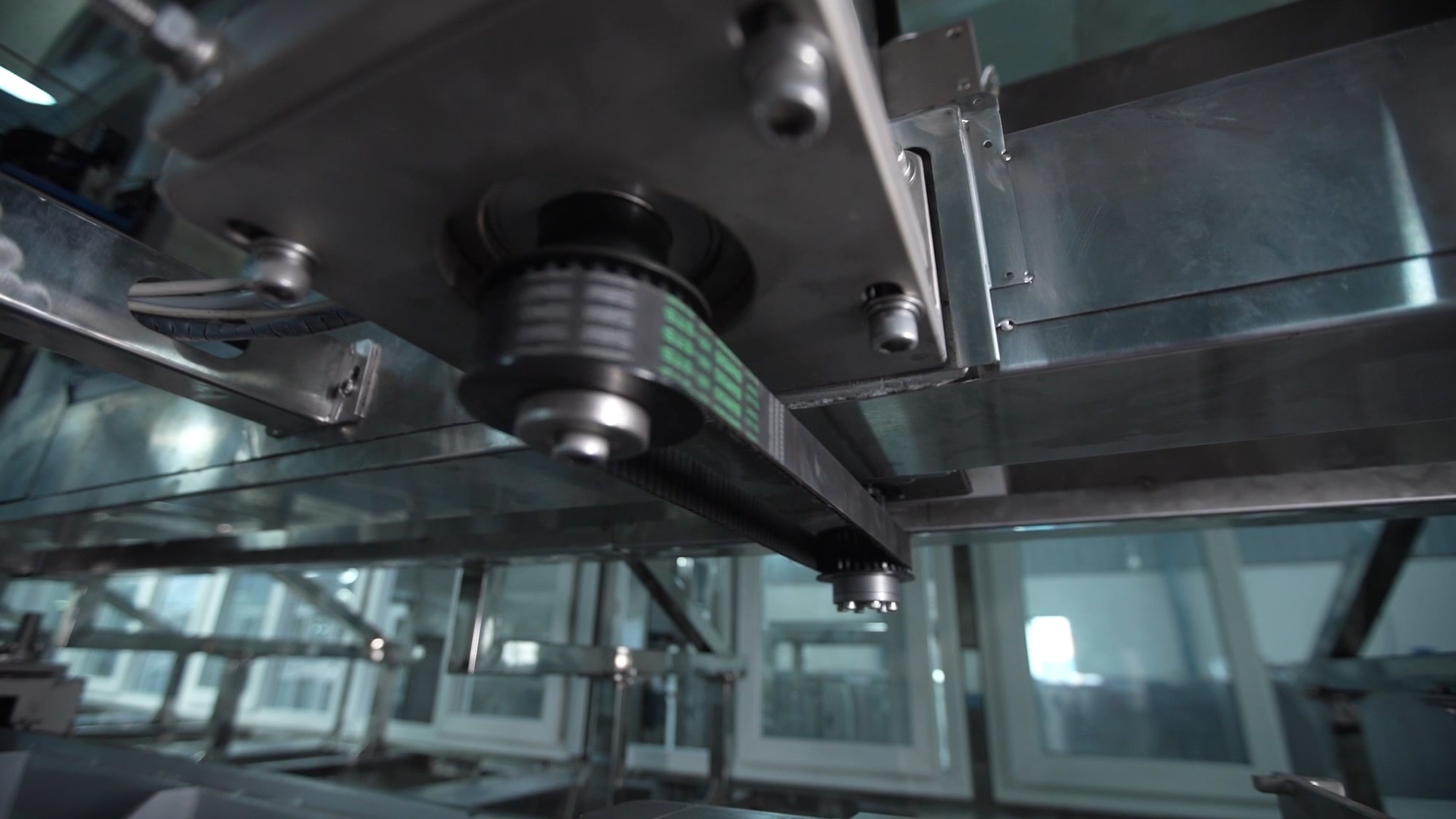

Custom conveyorized washers, often integrated with ultrasonic cleaning technology, find a wide range of applications across industries where thorough and automated cleaning is essential. Benefits of using custom conveyorized washers with ultrasonic technology include consistency, automation, and the ability to tailor the system to meet specific cleaning requirements. These systems are vital in industries where cleanliness, precision, and quality control are of utmost importance. These systems provide consistent and uniform cleaning results, as objects pass through the same cleaning process, ensuring that each part or component is cleaned to the same standard. It is essential in various industries where precision, consistency, and efficiency in the cleaning process are paramount. Their ability to provide thorough and uniform cleaning, combined with automation and customization, makes them a valuable asset in manufacturing and production environments. It can be used in fields like industrial parts cleaning, automotive parts cleaning, aerospace component cleaning, medical device cleaning, precision engineering and optics, bearing and gear cleaning and many more. Features: o Automated Cleaning o Consistent Results o Wide range of application Technical Specifications: o Brand: Waveultra o Power Input: 230V AC o Material: SS304 o Temperature Controller: Upto 60oc o No. of Stages: Multiple o Optional Stages: High-pressure Jet / Rinsing / Hot Air Drying