Revolutionizing Ultrasonic Cleaning: The Integration of Automation for Enhanced Efficiency.

The Evolution in Ultrasonic Cleaning: Automation Takes the Lead

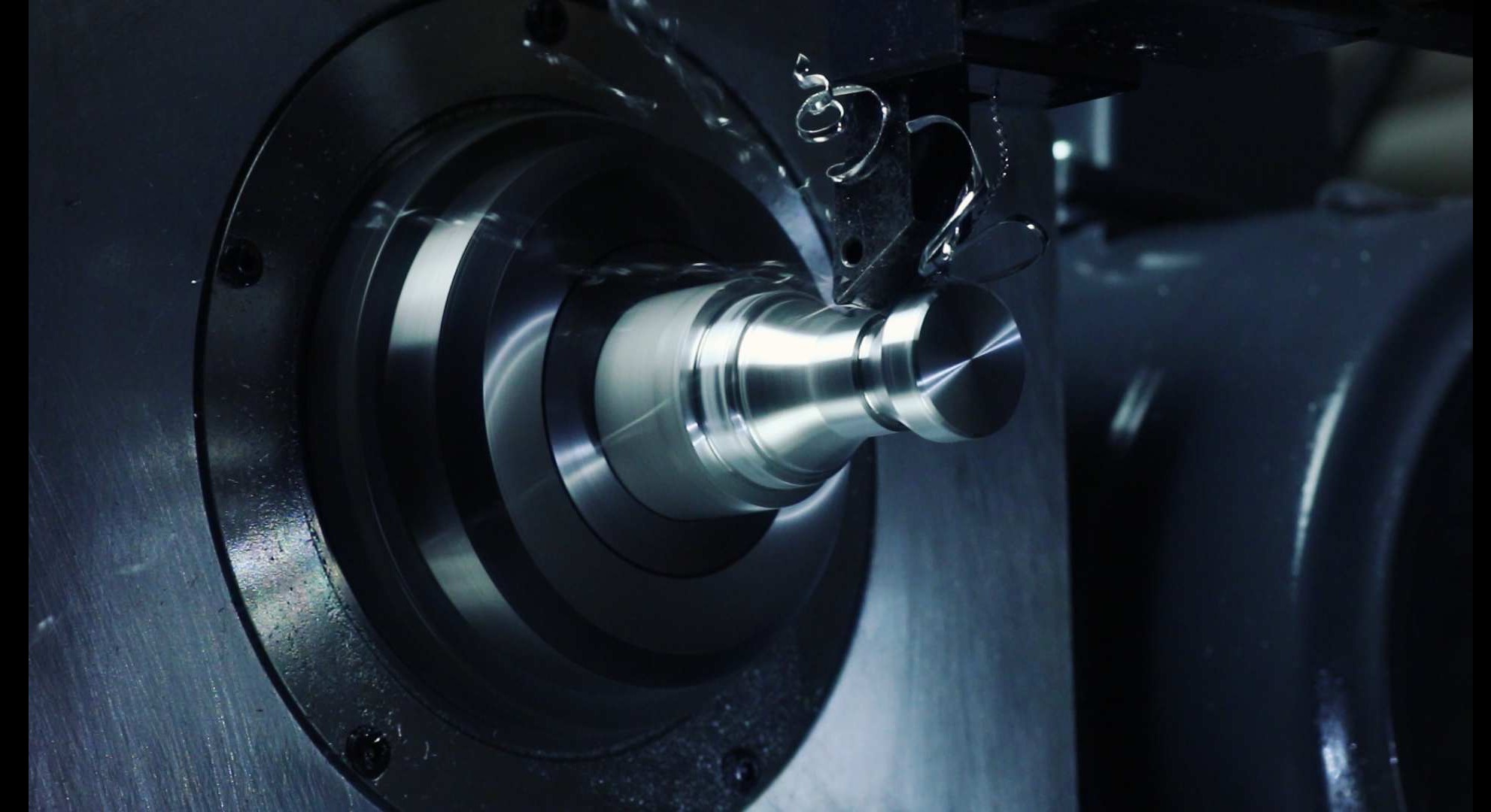

In the dynamic landscape of industrial cleaning processes, innovation continues to reshape the way we approach efficiency and precision. One such groundbreaking advancement is the integration of automation into ultrasonic cleaning systems.

- Enhanced Efficiency

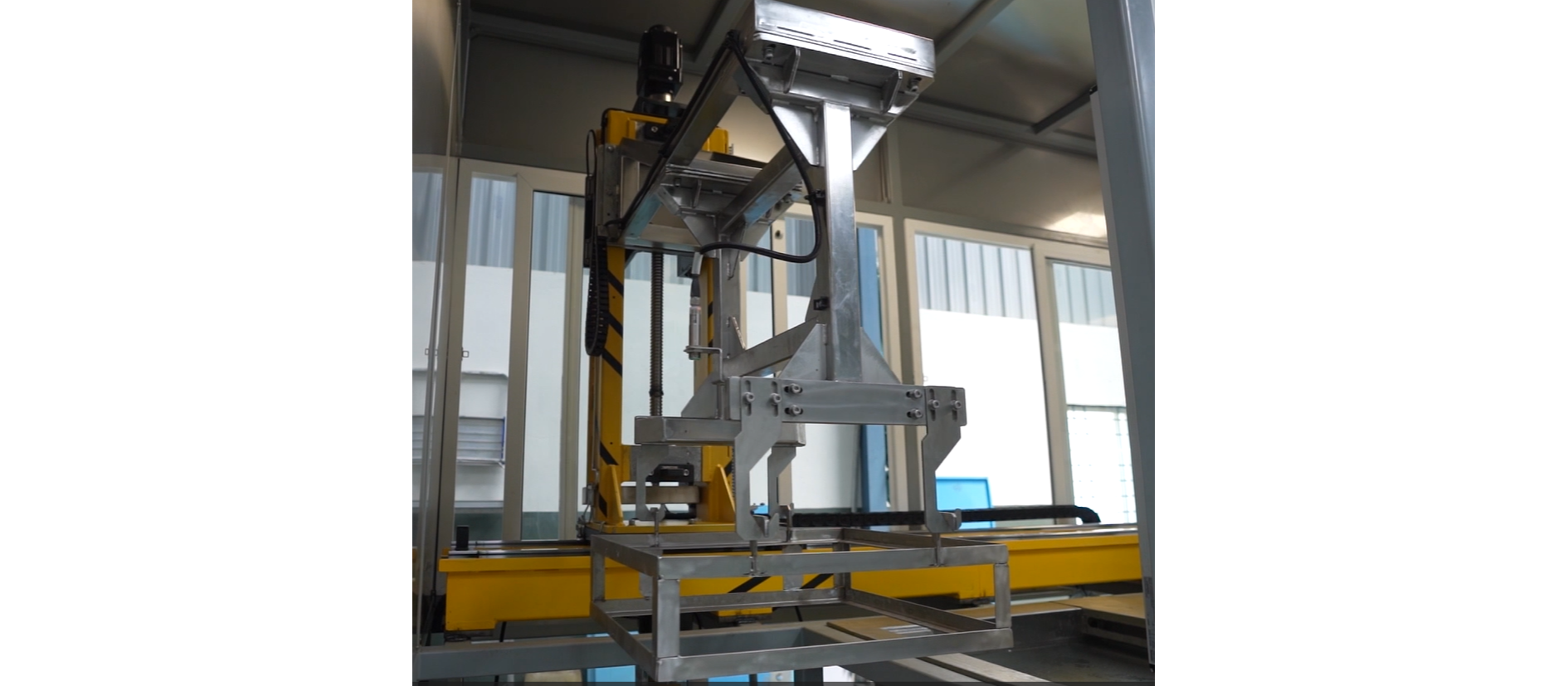

Automation brings a new level of efficiency to ultrasonic cleaning. With programmable cleaning cycles, precise temperature control, and real-time adjustments, the process becomes not only faster but also more effective. - Precision through Intelligence

Smart systems can handle intricate tasks such as loading, unloading, and positioning items within the cleaning tank and on the conveyors. This not only ensures consistent cleaning results but also opens the door to handling complex geometries and delicate components. - Consistency in Cleaning Results

Automated systems ensure a consistent and reproducible cleaning outcome. By precisely controlling parameters such as cleaning time, ultrasonic frequency, and temperature, automation eliminates variations caused by human factors, resulting in uniform cleanliness across batches.

Keywords

way

blog

Lead

door

realm

items

safety

loading

batches

conveyors

precision

new level

parameters

innovation

Conclusion

variations

Consistency

Integration

precise arms

Intelligence

Smart systems

cleaning time

human factors

cleaning tank

intricate tasks

Automated systems

dynamic landscape

complex geometries

delicate components

numerous advantages

transformative leap

uniform cleanliness

ultrasonic frequency

real-time adjustments

industrial cleanliness

unparalleled efficiency

groundbreaking advancement

precise temperature control

consistent cleaning results

ultrasonic cleaning systems

programmable cleaning cycles

industrial cleaning processes

reproducible cleaning outcome

Enhanced Efficiency Automation

sophisticated programmable cycles

Revolutionizing Ultrasonic Cleaning