Description

Product details

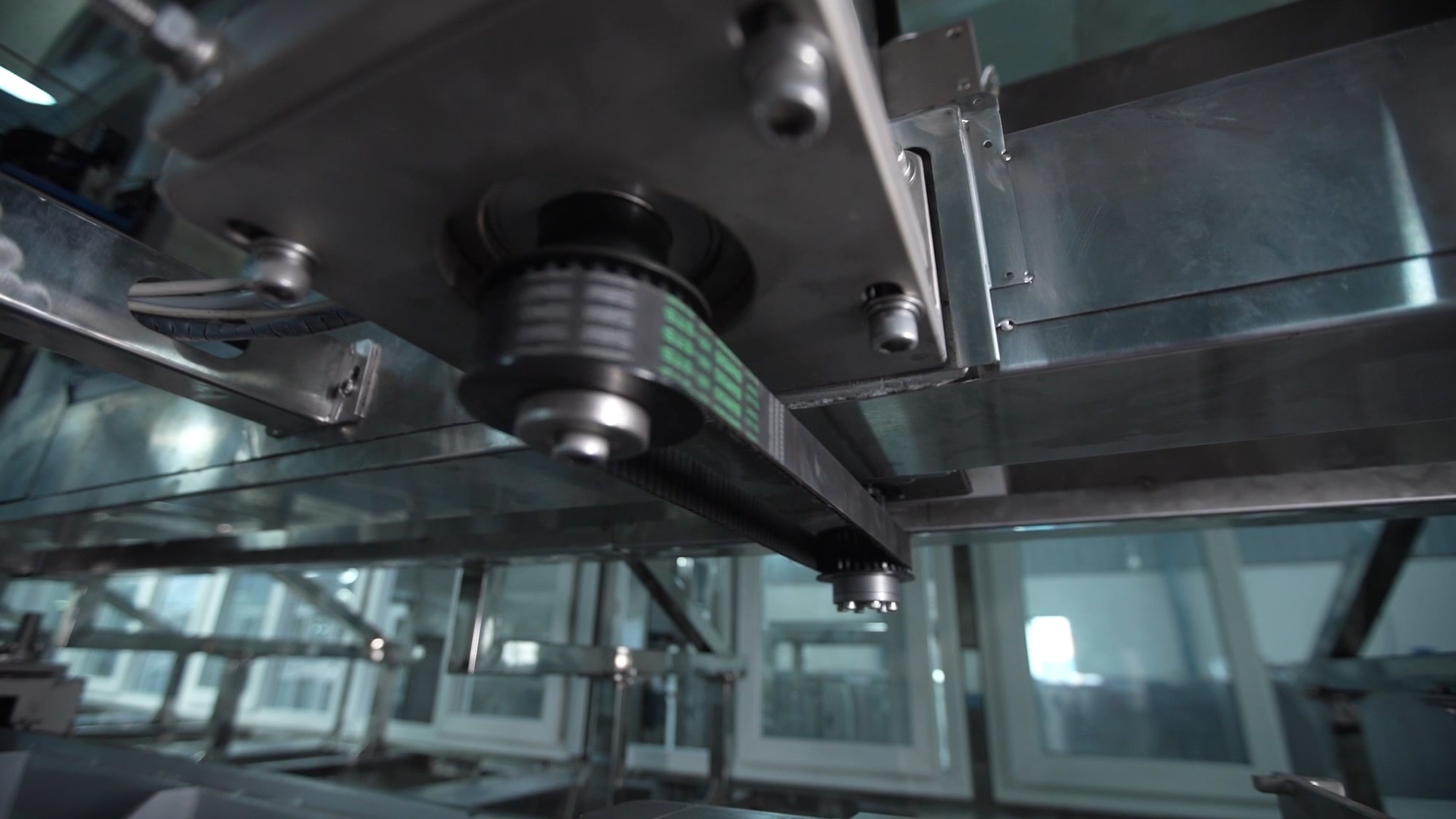

Wafer ultrasonic cleaners are specifically designed to clean individual semiconductor wafers one at a time. This single-wafer approach ensures that each wafer is cleaned with precision. These cleaners predominantly use water-based cleaning solutions or solvents that are compatible with the materials used in semiconductor fabrication. The choice of solution may vary depending on the type of contaminants to be removed. Most of our systems are fully automated and include handling mechanisms to transport wafers from loading to cleaning, rinsing, and drying stages, minimizing human contact and potential contamination. These cleaners are designed to remove submicron particles and nanometer-level residues, crucial for semiconductor manufacturing where even minuscule contaminants can lead to defects. The cleaning process ensures that wafers have particle-free surfaces, which is essential for lithography and other semiconductor fabrication steps. Features: o Fully Automated Systems o Minimum Human Interference o Usage of handling mechanisms Technical Specifications: o Brand: Waveultra o Power Output (Ultrasonic): 1 kW o Total Volume / Capacity: 64 Litres o Heater Power: 1 kW o Power Input: 230V AC o Frequency: 40 / 68 kHz o Material: SS304/SS316/PP o Basket Size(L x W x H): 350 x 350 x 300 mm o Transducers: PZT type o Temperature Controller: Upto 60oc o Cleaning Agent: Water based solution / Solvent o Tank Size (L x W x H): 400 x 400 x 400 mm o No. of Stages: Multiple o Optional Stages: Rinsing / Pickling / Hot Air Drying