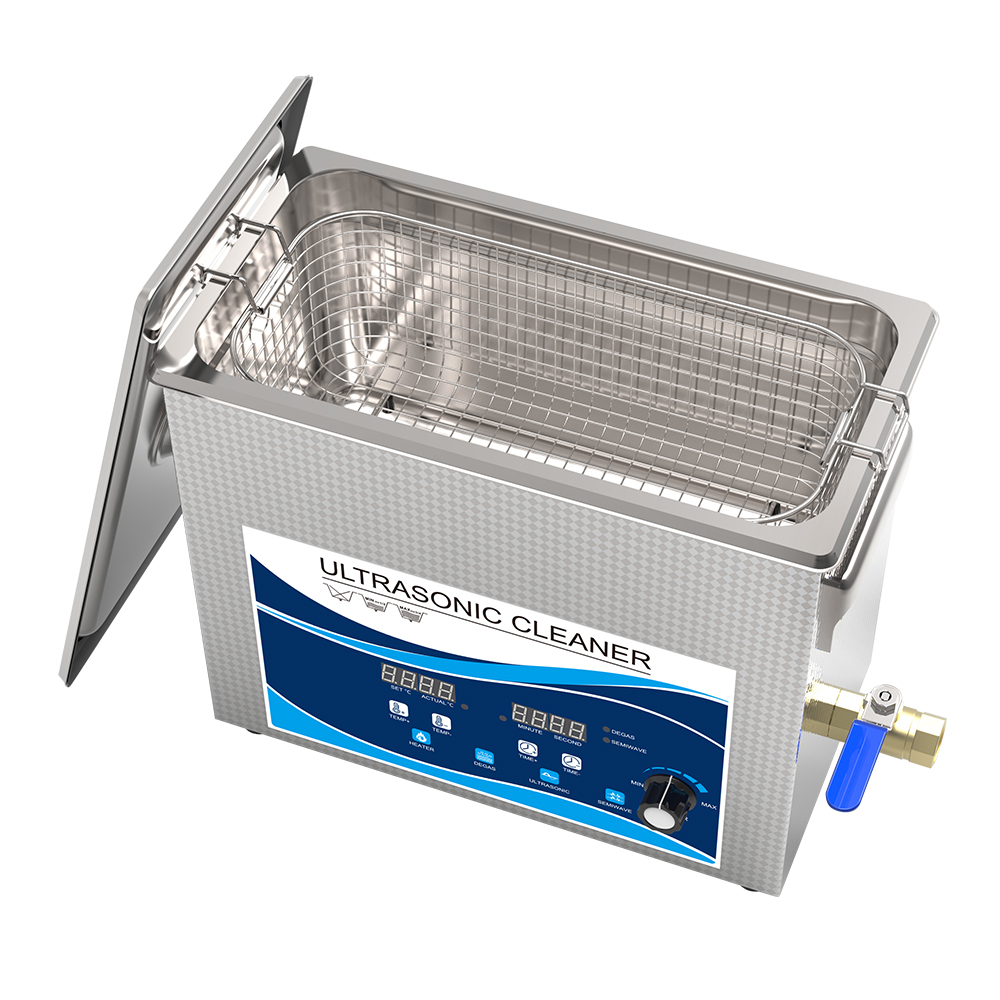

Waveultra’s hospital ultrasonic cleaners are crucial for the efficient and thorough cleaning of medical instruments, equipment, and devices to maintain a sterile and safe healthcare environment. Hospital ultrasonic cleaners are designed to be compatible with a wide range of medical instruments and materials, including stainless steel, glass, plastic, and rubber. These systems primarily use water-based cleaning solutions or specialized medical-grade detergents and disinfectants, ensuring the removal of contaminants and microorganisms. Hospital ultrasonic cleaners are effective at cleaning medical instruments, ensuring that they meet the highest hygiene and sterilization standards. The gentle yet effective cleaning process of ultrasonics ensures that medical instruments are cleaned without causing damage, preserving their structural integrity and longevity. Features: o Removes the toughest stains o Gentle Yet Effective o Suitable for OT and CSSD Technical Specifications: o Brand: Waveultra o Power Output (Ultrasonic): 1 kW o Total Volume / Capacity: 48 Litres o Heater Power: 1 kW o Power Input: 230V AC o Frequency: 27 / 40 / 68 kHz o Material: SS304 o Basket Size(L x W x H): 550 x 350 x 150 mm o Transducers: PZT type o Temperature Controller: Upto 60oc o Cleaning Agent: Water based solution / Solvent o Tank Size (L x W x H): 600 x 400 x 200 mm o No. of Stages: One