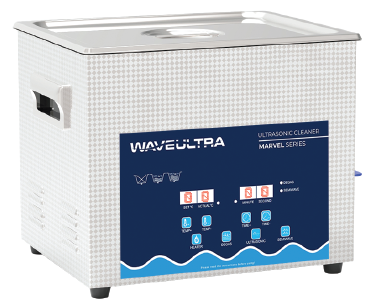

These types of cleaners are advanced cleaning systems that incorporate microprocessor control for precise, programmable, and efficient ultrasonic cleaning in a compact and space-saving design. These cleaners are used in a variety of industries, including electronics, jewellery, healthcare, and laboratories, where precision cleaning is required. These systems typically use water-based cleaning solutions or specialized detergents for various cleaning applications. Some models include heating elements to maintain the cleaning solution at an adjustable temperature, enhancing cleaning efficiency. These cleaners provide consistent cleaning results in each cycle, which is crucial for maintaining quality control in various industries. They contribute to the quality, efficiency, and consistency of the cleaning process. Features: o Equipped with heater function o Highly Effective o Adjustable Temperature Technical Specifications: o Brand: Waveultra o Power Output (Ultrasonic): 1.5 kW o Total Volume / Capacity: 60 Litres o Heater Power: 2 kW o Power Input: 230V AC o Frequency: 27 / 40 / 68 kHz o Material: SS304 o Basket Size(L x W x H): 450 x 350 x 200 mm o Transducers: PZT type o Temperature Controller: Upto 60oc o Cleaning Agent: Water based solution / Solvent o Tank Size (L x W x H): 500 x 400 x 300 mm o No. of Stages: One o Filtration: 10 Micron (Optional)