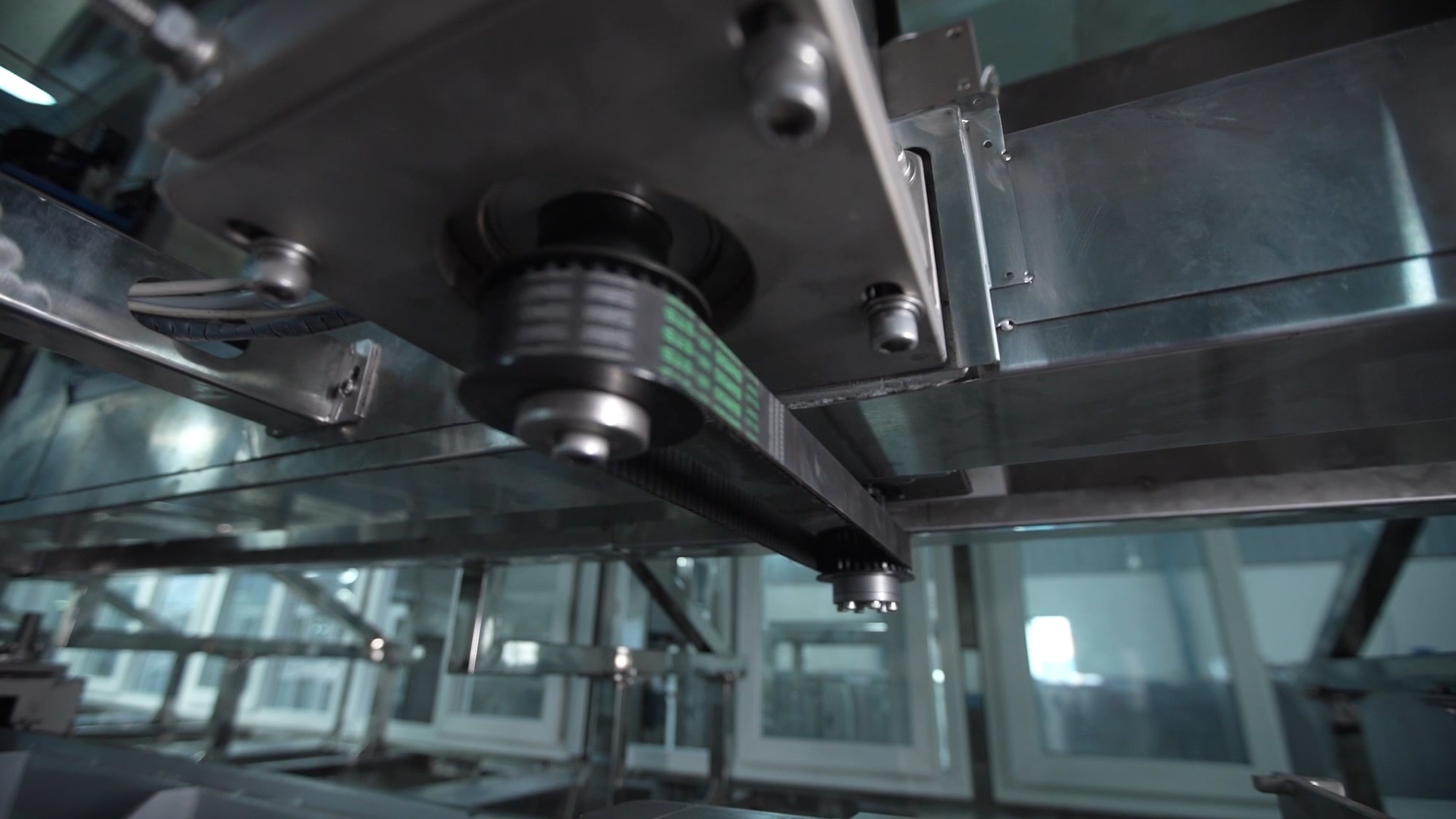

Rotary Drum Conveyorized Washers, when integrated into the ultrasonic cleaning process, offer a highly efficient and thorough method for cleaning various parts and components. In the process, components to be cleaned are loaded onto the conveyor system, which feeds them into the rotating drum. As the objects are loaded into the drum, they are submerged in a cleaning solution. Ultrasonic transducers in the drum emit high-frequency sound waves into the solution. These sound waves create cavitation bubbles, which collapse upon contact with the objects, dislodging contaminants from their surfaces. The drum begins to rotate, ensuring that all objects are exposed to the cleaning action evenly. This rotation helps to distribute the cleaning solution and ultrasonic energy throughout the drum, reaching all surfaces of the objects. Operators can often adjust the rotation speed of the drum to optimize the cleaning process. Slower speeds may be used for delicate components, while higher speeds can be employed for more robust parts. After the ultrasonic cleaning stage, the conveyor system typically moves the objects to a rinsing stage, where they are rinsed with clean water or a rinsing solution. Some systems include a drying stage, where objects are dried using hot air or other drying methods. This ensures that the cleaned components are completely dry before they are removed from the system. The conveyor system unloads the cleaned and dried objects, making them ready for the next phase of processing or assembly. Rotary Drum Conveyorized Washers with ultrasonic cleaning are employed in various industries, including manufacturing, aerospace, automotive, metalworking, and medical devices, where precision cleaning is critical to product quality and performance. Features: o Equipped with rotary drum o Multiple Stages o Adjustable rotation speed Technical Specifications: o Brand: Waveultra o Power Input: 230V AC o Material: SS304 o Temperature Controller: Upto 60oc o No. of Stages: Multiple o Optional Stages: High-pressure Jet / Rinsing / Hot Air Drying